| Complexity level: | 9 |

| Project cost ($): | 160 |

| Time required: | 1 hour to prepare, 1 day for the science project experiment |

| Material availability: | Motors will have to be purchased from an appropriate hobby store |

| Safety concerns: |

Hypothesis

Friction loss in a DC motor will increase as the power and size of the motor is increased.

Overview

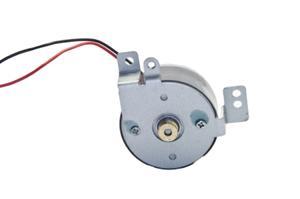

DC motors

A DC motor consists of a rotating part called an armature and a stationary part called a stator. The stationary stator will have coils made out of copper wire called field coils. The rotating armature will also have copper coils wrapped around an iron core. A metal shaft which can rotate on the bearings is located in the middle of the metal core. The wires that come out of the armature coils will terminate at the commuter. This is the place where electrical contact between the armature and the stator is made.

The function of the motor is to convert electrical power into mechanical power. However, not all the electrical energy supplied to the motor can be converted into mechanical energy. Some of the power will be lost and be dissipated as heat from the surface of the motor.

Several types of losses will occur in a motor. The current that flows in the coil will cause copper losses in the stator and armature. The iron core in the armature will produce core losses. Friction losses will happen at the bearing and brushes. The magnetic leakage will cause stray load losses.

Scientific Terms

Materials

- The materials required for this science project:A DC 24V, 500W power supply

- A DC 24V, 30W servomotor

- A DC 24V, 50W servomotor

- A DC 24V, 70W servomotor

- A DC 24V, 100W servomotor

- A multi meter

- An ammeter

- A stopwatch

MEL Physics — monthly physics experiment kits delivered to your door. (Affiliate link)

See what’s includedProcedure

1. For this science project, the independent variable is the rating of the DC motor used – 30 watt, 50 watt, 70 watt and 100 watt. The dependent variable is the energy lost due to friction in the DC motor. This is determined by measuring the voltage, current and time taken for the motor to stop after the power is turned off. The constants (control variables) are the size of the power supply and the type of DC motor used.

2. The experiment is done by selecting 4 different ratings of DC motors from the same series and manufacturer. This is to ensure that the construction of the DC motors is the same and to eliminate the friction factor that may result from different types of construction. The suggested power rating for this experiment is 30 watt, 50 watt, 70 watt and 100 watt.

3. The DC motor is connected to the 500 watt DC power supply. It is allowed to turn freely without any load. The multi meter and ammeter are used to measure the input current and DC voltage at the motor input. The measurements are recorded in the table below.

4. The power supplied to the motor is calculated as below :

Power (W) = Input DC voltage (V) x Input DC current (A)

This power will be the work (Joule) required to be done by the internal friction of the motor, in order to bring the motor to a stop.

5. The power to the motor is switched off and the stopwatch started. The time needed for the motor to stop is recorded in the table given below.

6. The amount of friction power required to bring the motor to stop is calculated as :

Friction power (W) = work done to stop motor (Joule) / time to stop motor (seconds)

The results are recorded in the table given below.

Results

It was observed that as the motor rating and size increases, the amount of friction power increases.

|

Measurement |

Friction losses and motor rating |

|||

|

30W |

50W |

70W |

100W |

|

|

DC Volt (V) |

12.0 |

12.0 |

12.0 |

12.0 |

|

DC Current (A) |

0.22 |

0.31 |

0.42 |

0.63 |

|

Power (V) x Current (W) |

2.64 |

3.72 |

5.04 |

7.56 |

|

Time (seconds) |

3.33 |

2.78 |

2.66 |

2.81 |

|

Friction loss (W) |

0.79 |

1.34 |

1.89 |

2.63 |

The materials required for this science project:

Conclusion

The hypothesis that friction loss in a DC motor increases as the power and size of the motor are increased, is proven to be true.

Electric motors are used to convert electrical power into mechanical power. They are normally used in fans, pumps, blowers, tools, electrical appliances and hard dick drives. Some very tiny motors are also found in wrist watches. Larger motors are used in ship and aircraft propulsion systems

Also consider

Try to repeat the experiment to compare the efficiency of motors.

The experiment can also be repeated using AC motors.

References

Electric motor - http://en.wikipedia.org/wiki/Electric_motor

Motor losses - http://tristate.apogee.net/mnd/msimovr.asp

DC motor theory - http://zone.ni.com/devzone/cda/ph/p/id/52